Method of using copper in sheet metal manufacturing !

The conductivity and thermal conductivity of copper are one of its advantages in sheet metal manufacturing. Copper is an excellent conductive material, second only to silver, making it ideal for electrical applications. The use of copper plates for electrical needs in buildings can ensure good current conduction and heat dissipation, in order to maintain the normal operation and safety of equipment.

In addition, the corrosion resistance of copper is also one of its advantages in sheet metal manufacturing. Compared to standard steel and aluminum, copper is more resistant to corrosion under atmospheric conditions. Although copper is also influenced by some influencing elements, its ability to resist corrosion is relatively good under normal conditions, making it a reliable material choice.

Advantages of Choosing Copper Plate Processing

Strong ductility and plasticity enable the manufacturing of products of various shapes.Good corrosion resistance, suitable for long-term use and applications exposed to atmospheric environments.

Excellent conductivity and thermal conductivity make it suitable for applications in electrical and thermal management.

When considering the selection of sheet metal manufacturing materials, copper is a neglected but advantageous choice, particularly suitable for meeting building and construction needs.

The Best Reason for Using Copper in Sheet Metal Manufacturing

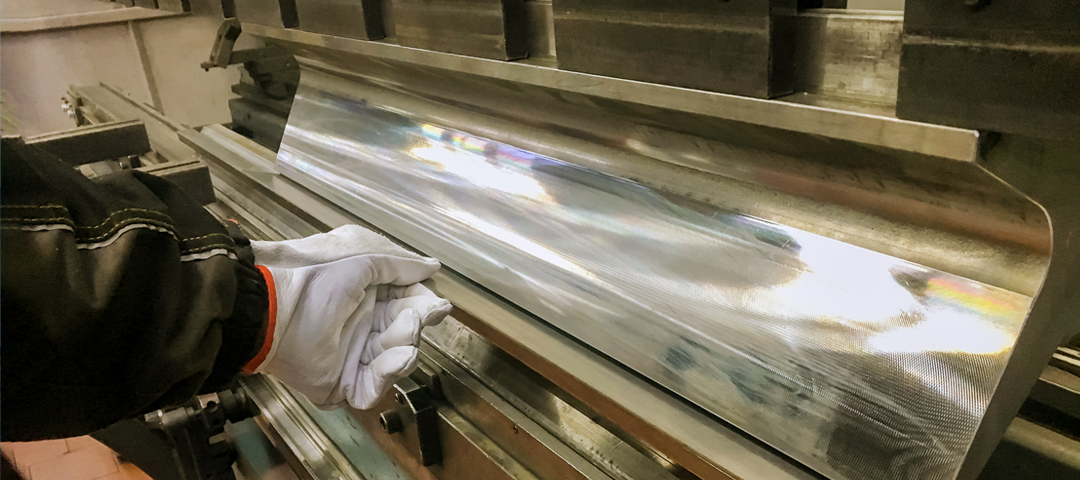

Strong ductility and extensibility

Copper has excellent ductility and ductility, which can be easily processed into various shapes and sizes of parts. This makes copper an ideal material for manufacturing complex and precision components.Good conductivity and thermal conductivity

Copper is an excellent conductive and thermal conductive material, second only to silver. In electrical and thermal management applications, copper can provide excellent current conduction and heat dispersion, ensuring the normal operation and safety of equipment.Corrosion resistance

Compared to standard steel and aluminum, copper is more resistant to corrosion under atmospheric conditions. It can resist oxidation and corrosion, thereby extending the service life and reliability of the parts.

Beautiful appearance and texture: Copper has a unique metallic texture and color, adding a high-end and exquisite appearance to the manufactured products. This makes copper widely used in the fields of architecture and decoration, adding unique visual appeal to the project.

Sustainability

Copper is a recyclable and reusable material with low environmental impact. In the pursuit of sustainable development and environmentally friendly manufacturing processes, choosing copper can reduce dependence on limited resources and reduce waste generation.The use of copper in sheet metal manufacturing has many advantages, including its ductility, conductivity, thermal conductivity, corrosion resistance, appearance and texture, and sustainability. According to specific application requirements, selecting copper as a material can provide high-quality manufacturing products and meet the requirements of the construction and construction fields.

The Application of Copper Plate in Various Fields

Electrical and Electronic Fields

Due to the excellent conductivity of copper, copper plates are commonly used in the manufacturing of conductive components for circuit boards, cables, wires, transformers, generators, motors, and other electronic devices.Architecture and Architectural Decoration

Copper plates are often used in buildings for roofs, facades, ceilings, wall panels, doors and windows, and other parts. It has good weather resistance and corrosion resistance, which can give buildings a unique appearance and texture.automotive industry

Copper plates are used in automotive manufacturing to manufacture radiators, cooling systems, exhaust systems, braking systems, and electrical components. Its thermal conductivity and corrosion resistance make it an important material in the automotive industry.Chemical and marine industries

Copper plates are commonly used in the manufacturing of equipment such as heat exchangers, distillation towers, storage tanks, pipelines, and valves in chemical and marine industries. Capable of withstanding the requirements of high temperature, high pressure, and corrosive environments.Food processing and beverage industry

Copper plates are widely used in the food processing and beverage industry to manufacture containers, pipelines, stoves, and heating equipment. Copper has good thermal conductivity, which helps with uniform heating and insulation of food.Decorative art

Due to the unique color and luster of copper, copper plates are commonly used in the production of artworks, sculptures, decorations, furniture, lamps, and decorations.

Copper plates are also used in various industries such as aerospace, metallurgy, medical equipment, and communication equipment. The diversity and adaptability of copper sheet make it a widely used material, playing an important role in various fields.

Whatsapp

Whatsapp

Email

Email

Get a Auota

Get a Auota