What can you print in 3D?

3D printing technology can manufacture various types of objects.

Rapid prototyping

Rapid prototyping typically uses 3D printing technology to manufacture prototypes. Prototypes of high-quality parts can be quickly produced, such as complex shapes, rapid manufacturing, customization, and low cost. Assist designers in product validation and design improvement, and save time and costs in the product development process.

Home and Decoration

Through 3D printing, various household items and decorations can be manufactured, such as lamps, vases, decorative sculptures, etc. This allows designers and consumers to customize personalized household items.

Accessories and components

3D printing can produce various accessories and components for repairing or replacing damaged items. This technology makes the manufacturing of specific accessories more convenient and economical.

Medical field

3D printing can produce medical devices, prosthetics, dental models, and more. In addition, personalized medical devices and prosthesis manufacturing can also be achieved through 3D printing.

Education and research

3D printing can be achieved by manufacturing models and physical objects, allowing students and researchers to better understand and study various concepts and experiments.3D printing technology can manufacture various types of objects, from prototypes to home decorations, to medical devices and educational models. The flexibility and customization capabilities of this technology have brought innovation and convenience to many fields.

Advantages and disadvantages of 3D printing

advantage

3D printing can quickly manufacture objects without the need to manufacture molds or wait for delivery times in traditional production processes.

3D printing can be customized according to individual needs, making it easy to achieve personalized design and customized products.

Traditional manufacturing processes often generate a large amount of waste and by-products, while 3D printing is an additive manufacturing process that can reduce waste.

3D printing can create complex geometric shapes, both internal and external, by stacking materials layer by layer.

3D printing can promote innovation and rapid iteration, enabling rapid validation of design concepts and prototyping, thereby shortening the product development cycle.

shortcoming

At present, the types of materials available for 3D printing are relatively limited. Despite the continuous emergence of new materials, they still cannot compete with the diversity of materials in traditional manufacturing processes.

The size limit of 3D printing depends on the working area of the printer, and larger objects may need to be decomposed into multiple parts for printing and subsequent assembly. In addition, 3D printing typically has a slower construction speed than traditional manufacturing processes.

Compared to traditional manufacturing processes, some 3D printing technologies may produce rougher surface quality and may require post-treatment processes to improve surface smoothness.

Although 3D printing can save costs in some specific applications, in other cases, 3D printing may still be more expensive, especially for mass production.

3D printing involves the use of specific devices and technologies, requiring professional knowledge and skills to operate and maintain printers, which may be challenging for some users.

Although 3D printing has many advantages, there are also some limitations and limitations. With the continuous development and innovation of technology, these limitations are gradually decreasing, and it is expected that 3D printing will continue to develop and be more widely used in the future.

How long does 3D printing take?

The time required for 3D printing depends on multiple factors, including the size and complexity of the printed object, printing technology, printing resolution, and the device used. Small and simple objects may only take a few minutes or hours to complete printing, while larger and complex objects may take tens of hours or even days to complete.

In addition, the printing speed also depends on the selected printing technology. Some technologies, such as FDM (Melt Deposition Modeling), are usually slower because they require the material to be extruded layer by layer and waiting for the material to cool and solidify. Other technologies, such as SLA (light curing), typically have a faster speed due to their ability to cure the entire layer simultaneously.

Resolution is also one of the factors that affects printing time. Higher resolution means that the printer requires more layers and details, thereby increasing printing time. On the contrary, lower resolutions can reduce printing time, but may sacrifice some details and surface quality.

It should be noted that the printing time only refers to the actual printing time, and does not include preliminary preparations such as designing the model, slicing (dividing the model into layers), as well as calibration and preparation work before printing.

Therefore, accurately estimating the time required for 3D printing is complex, depending on multiple factors and may vary depending on different situations. The best method is to use slicing software and printer parameters to estimate the printing time before starting printing.

3D printing type

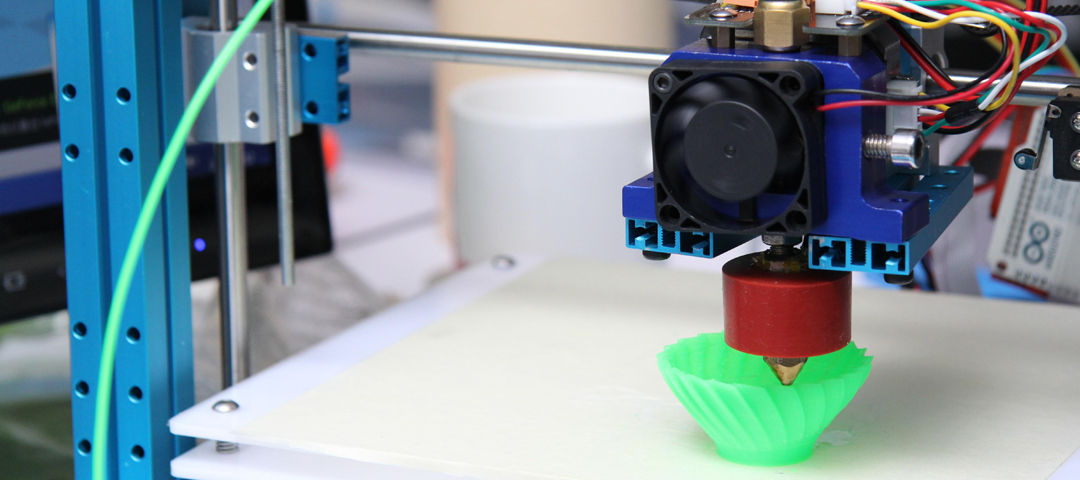

FDM: FDM is one of the most common 3D printing technologies. By extruding thermoplastic materials such as ABS or PLA from the nozzle, the object is constructed layer by layer. This technology is easy to use and widely applied, suitable for prototyping, small-scale production, and personalized items.

SLA: SLA uses ultraviolet laser beams to cure liquid photosensitive resins. By solidifying liquid resin layer by layer into a solid, objects with high precision and smooth surfaces can be created. SLA is typically used to create high-quality models, molds, and visual effects.

SLS: SLS uses a laser beam to sinter powder materials (usually nylon, nylon glass fibers, etc.) together and build objects layer by layer. SLS is suitable for producing durable, complex parts and functional prototypes.

DLP: DLP is similar to SLA, using photosensitive resin, but curing the resin by using a digital projector instead of a laser. DLP printing speed is fast, suitable for making small and high-resolution objects.

Binder Jetting: This technology uses inkjet printing heads to combine powder materials (usually sandstone or metal powder) with binders. After being stacked layer by layer, the object is solidified through baking or other post-processing steps. Binder Jetting is suitable for fast printing of metal and ceramic products.

EBM: EBM uses an electron beam to melt and solidify metal powder, constructing objects layer by layer. This technology is suitable for manufacturing high-strength metal parts, such as components in the aerospace and medical fields.

These are just a few common types of 3D printing, and with the continuous progress of technology, many other types of 3D printing technologies are constantly emerging. Each type of 3D printing technology has its unique advantages and applicable fields, and selecting the appropriate technology based on needs is very important. Whatsapp

Whatsapp

Email

Email

Get a Auota

Get a Auota