What is CNC Prototype machining?

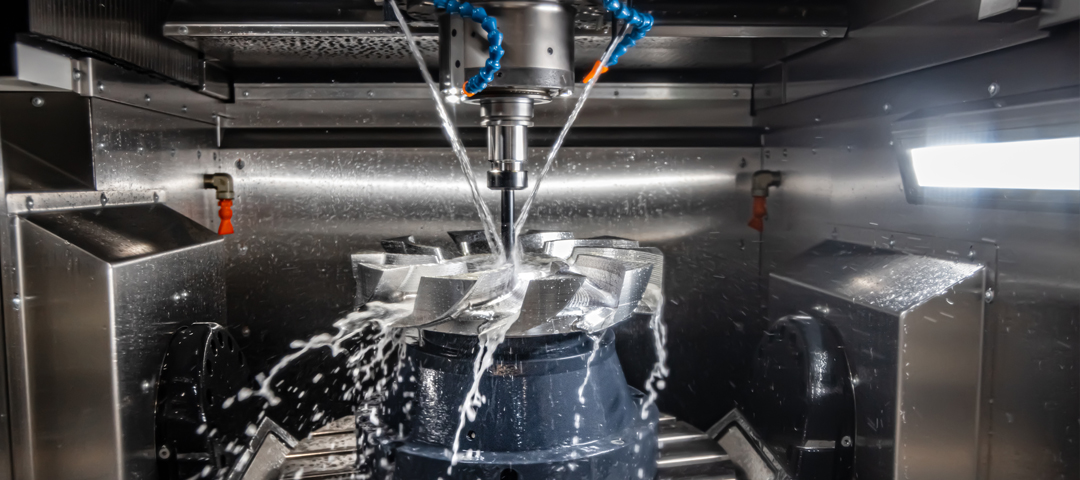

CNC Prototyping machining is a process used to manufacture product prototypes, aimed at verifying and evaluating the feasibility, functionality, and appearance of product design. Prototyping is usually carried out in the early stages of product development for testing and improvement before mass production.

Prototyping can be achieved through various methods, such as traditional machining, rapid prototyping techniques (such as 3D printing), CNC machining, injection molding, etc. The specific machiningmethod depends on the material, complexity, and requirements of the product.

The main purpose of CNC prototype machining

Design verification: By manufacturing prototypes, designers can verify the feasibility and reliability of product design. Prototypes can be used to test the functionality, assembly, durability, and other aspects of a product, in order to make necessary modifications and improvements before mass production.

Provide demonstrations and demonstrations: Prototyping can provide actual product demonstrations for customers, investors, or stakeholders. By touching, manipulating, and visually inspecting the prototype, people can better understand the characteristics and potential value of the product.

Reduce costs and time: Through prototyping, problems in product design can be identified and resolved early on, thereby avoiding expensive errors and repairs during mass production. This helps to shorten the product development cycle and reduce development costs.

Promoting collaboration and communication: Prototyping can provide a common reference point for designers, engineers, and manufacturers, promoting collaboration and communication among teams. Through actual touch and use of prototypes, team members can better understand the features and requirements of the product, and work together to drive the progress of the project.

Prototyping is a crucial step in the product development process aimed at validating design, providing demonstrations, reducing costs and time, and promoting teamwork. The successful development and improvement of the product provide important support.

Why is CNC machining suitable for the prototyping process?

CNC machining is an automated machining method controlled by computers, which is suitable for the prototyping process for the following reasons:

High precision

CNC machining can achieve very high precision and repeatability, and can manufacture prototypes with accurate dimensions and fine details. This is crucial for verifying the accuracy and functionality of product design.

Multi material processing

CNC machiningcan handle various types of materials, including metals, plastics, wood, etc. This makes CNC machining very suitable for manufacturing prototypes, as product prototypes typically require the use of different types of materials to simulate the characteristics of the final product.

Flexibility

CNC machining can be quickly adjusted and modified according to design requirements. During the prototype production process, multiple iterations and improvements may be required, and CNC machining can flexibly adapt to these changes and quickly generate new prototypes.

High degree of automation

CNC machining is an automated machining method that controls mechanical tools through computer programs for operation. This high degree of automation enables CNC machining to efficiently manufacture prototypes, reduce human errors, and improve production efficiency.

Reproducibility

CNC machining can be carried out according to the precise instructions on the design drawings, ensuring the accurate replication of the prototype. In this way, when multiple identical prototypes are needed for testing or demonstration, CNC machining can ensure that each prototype has consistent dimensions and characteristics.

CNC machining is suitable for the prototype production process because it can provide high precision, multi material processing, flexibility, high automation, and replicability. These characteristics make CNC machining an ideal choice for rapid prototyping, helping designers and engineers validate and improve product design.

CNC Prototype Production Operations

CNC prototyping is an important part of the design and development process, used to validate and demonstrate the concepts and functions of a product.

Setting goals

Clarify the goals and purposes of the prototype to provide direction for the production process.

Collect requirements

Communicate with stakeholders to understand their needs and expectations, and translate these requirements into the functionality and features of the prototype.

Develop a design plan

Based on the collected requirements, develop a prototype design plan, including interface layout, functional processes, etc.

Choose Prototype Tool

Select the appropriate prototype tool based on requirements and design solutions. Common prototype tools include Axure, Sketch, Adobe XD, InVision, etc.

Create sketch: Use paper, pen, or prototype tools to create preliminary sketches to quickly capture the concepts and basic layout of the design.

Design Interaction

Create an interaction prototype using prototype tools based on the sketch. Add pages, links, and basic interaction effects to simulate the interaction process between users and products.

Iterative optimization

Share prototypes with team members and stakeholders, and collect feedback. Continuously optimize the prototype based on feedback until the expected functionality and user experience are achieved.

Testing and validation

Use prototypes for user testing, observe user behavior and feedback. Based on the test results, further improve the prototype.

Documentation and delivery

After the prototype is completed, organize relevant documents, record the functions and features of the prototype, and share and deliver them with relevant personnel.

Communication and Collaboration

Maintain good communication and collaboration with team members and stakeholders throughout the entire prototype production process to ensure the accuracy and effectiveness of the prototype.

Whatsapp

Whatsapp

Email

Email

Get a Auota

Get a Auota