What is sheet metal processing?

Sheet metal processing refers to the process of cutting, bending, stamping, stretching, welding, and other processing processes on metal sheets to produce the desired shape, size, and structure.

The working principle of sheet metal manufacturing process

The sheet metal manufacturing process relies on appropriate molds and processes to perform precise cutting, bending, stamping, and other operations on metal sheets. The goal of these processes is to convert the original metal sheet into components or products that meet the design requirements in terms of shape, size, and structure through appropriate processing methods and tools.

Steps for sheet metal processing

stores reserveSelect appropriate metal plates, perform material pre-treatment according to product requirements and design drawings, such as cutting into the required size plates.

Design and mold manufacturingAccording to the design requirements of the product, draw engineering drawings, and make corresponding molds or fixtures. The mold is used for cutting, bending, stamping and other processing processes to ensure that the metal sheet can achieve the required shape and size.

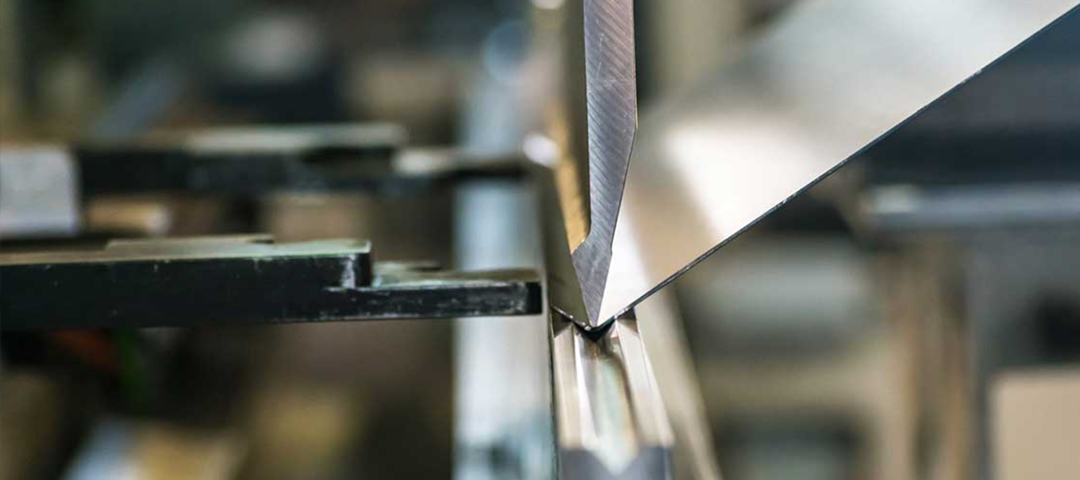

cuttingUse cutting machinery, laser cutting and other processes to cut metal sheets into the required shapes and sizes according to design requirements.

Bending and FormingBend metal sheets into the desired curves, angles, or shapes through mechanical bending, rolling, bending, and other processes. This is usually achieved by placing the sheet metal on the bending mold and applying appropriate force.

Stamping and stretchingUse stamping molds for processing such as punching, stretching, convexity, and concavity to create the required holes, concave and convex shapes, or textures. This is usually achieved by placing the sheet metal on the stamping die and applying pressure or impact.

Welding and assemblyConnect and assemble metal plates through welding processes to form complete components or products. Various methods can be used for welding, such as argon arc welding, laser welding, etc.

surface treatmentSurface treatment of metal sheets, such as spraying, electroplating, polishing, etc., to improve appearance, corrosion resistance, and decorative properties.

Inspection and Quality Control

Inspect and control the quality of manufactured sheet metal components to ensure they meet design requirements and quality standards.

Types of sheet metal

Sheet metal bendingBend the metal sheet according to the design requirements to form an angle or curve. This type of sheet metal is widely used in the manufacturing of products such as chassis, cabinets, and covers.

Sheet metal stampingUse stamping molds to process metal sheets through punching, stretching, convexity, and concavity processes, forming the required holes, concave and convex shapes, or textures. Stamped sheet metal is often used for manufacturing electronic equipment casings, automotive parts, etc.

Sheet metal weldingBy welding processes, multiple metal plates are connected together to form a complete component or product. Sheet metal welding is widely used in fields such as automotive manufacturing and aerospace.

Sheet metal stretchingExtend the metal sheet through a stretching process to achieve the desired length or shape. This type of sheet metal is used for manufacturing products such as pipes and conduits.

Sheet metal rolling and bendingRoll metal sheets through rollers or rollers to bend them into the desired shape. This type of sheet metal is often used for manufacturing cylinders, curved components, etc.

Sheet metal punchingCreate holes on metal sheets through punching technology to meet different connection or fixation requirements. Sheet metal punching is commonly used in the manufacturing of electrical boxes, ventilation holes, etc.

Precision cutting of sheet metalUse high-precision cutting techniques such as laser cutting and water jet cutting to accurately cut metal sheets to meet high-precision dimensional requirements.

Application of Sheet Metal Processing and Manufacturing

Automobile manufacturingSheet metal manufacturing plays an important role in the automotive manufacturing industry. Applied in the manufacturing of body shells, doors, hood, roof and other components.

Electronic and electrical equipmentSheet metal manufacturing is used to manufacture electronic equipment casings, chassis, panels, etc. Applied in the manufacturing of electrical control cabinets, distribution boxes, and communication equipment casings.

Architecture and Building MaterialsSheet metal manufacturing is applied in the construction field, such as manufacturing roofs, wall panels, door and window frames, staircase handrails, etc. Applied to manufacturing building facilities such as ventilation ducts, air conditioning ducts, and smoke exhaust systems.

AerospaceSheet metal manufacturing is very important in the aerospace field, used for manufacturing aircraft shells, wings, doors, etc. Applied in the manufacturing of aerospace devices and missile casings.

Agriculture and agricultural machinerySheet metal manufacturing is applied in the field of agricultural machinery, such as manufacturing agricultural vehicles, agricultural machinery components, and agricultural machinery shells.

Medical equipment: Sheet metal manufacturing is used to manufacture medical equipment casings, instruments, and equipment brackets.

Home and Home AppliancesSheet metal manufacturing is applied in the fields of home and home appliances, such as manufacturing kitchen utensils, home appliance shells, furniture, and decorations.

Oil and Natural GasSheet metal manufacturing is used to manufacture equipment and containers in the oil and natural gas fields, such as oil tanks, natural gas pipelines, and petrochemical equipment.

food industrySheet metal manufacturing is applied in the food processing and packaging industry, such as manufacturing food machinery equipment, food processing containers, and packaging equipment.

Whatsapp

Whatsapp

Email

Email

Get a Auota

Get a Auota