What is 3D printing? How does 3D printing work?

What is 3D printing?

3D printing is a manufacturing technology, also known as additive manufacturing. A digital model created using computer-aided design (CAD) software that constructs the physical form of an object by stacking materials layer by layer.

In the 3D printing process, the first step is to use CAD software or 3D scanners to create or obtain a digital model of the object. Then, input the model into a 3D printer, which will add materials layer by layer according to the specified parameters and requirements until the complete object is constructed.

Different 3D printing technologies use different materials and working principles. Common materials include plastics, metals, ceramics, and biomaterials. According to the selected printing technology, the material can be in powder, liquid, or linear form.

The advantage of 3D printing technology lies in its ability to achieve highly personalized and customized manufacturing, reducing waste and costs in traditional manufacturing processes. It also provides the ability to quickly prototype and validate designs and concepts.

3D printing has been widely used in many fields, including industrial manufacturing, healthcare, aerospace, architecture, and education. Innovation and creation provide new possibilities and drive the development of manufacturing in many industries.

What are the main methods of 3D printing?

3D printing is a manufacturing technique that converts digital models into physical objects.

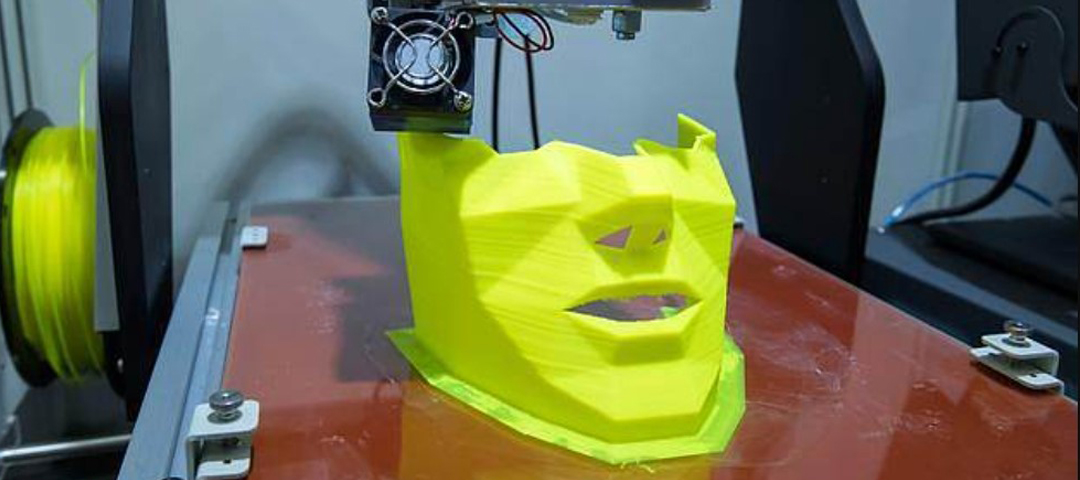

FDM: FDM is one of the most common 3D printing methods. Create objects by melting hot plastic filaments (usually ABS or PLA) from the nozzle and stacking them layer by layer. The nozzle moves along a predetermined path, gradually accumulating plastic materials to form a 3D model.

SLA: SLA uses liquid photosensitive resin and ultraviolet laser to create objects. The photosensitive resin is cured by ultraviolet laser irradiation, gradually forming 3D printed objects. This method usually has higher accuracy and surface quality.

SLS: SLS uses high-power lasers to sinter powder materials, typically thermoplastic materials such as nylon and polyamide. The laser beam scans and sinters the powder layer, gradually constructing the object.

DLP: DLP uses principles similar to SLA, but uses digital projection technology. Use liquid photosensitive resin and digital light processor (DLP) to project images onto the resin and solidify each layer.

EBM: EBM uses an electron beam to melt metal powder layer by layer, forming a 3D printed metal object. This method is usually used for metal printing and has high accuracy and strength.

SLM: SLM is also a metal 3D printing technology that uses lasers to melt metal powder layers and stack them layer by layer to form 3D printed metal objects. Compared to EBM, SLM uses lower laser power.

These are common 3D printing methods, each with its unique advantages and applicability. The selection of a suitable method depends on factors such as the required materials, accuracy, printing speed, and application field.

What are the advantages of 3D printing technology?

3D printing technology has many advantages, making it widely used in various fields.

High degree of design freedom: 3D printing can achieve highly personalized and customized manufacturing, allowing designers to freely create complex shapes and structures without being limited by traditional manufacturing methods.

Rapid prototyping: 3D printing can quickly create prototypes of objects, providing the ability to quickly validate designs and concepts. This helps accelerate the innovation and product development process.

Reducing waste and cost: Compared to traditional material reduction manufacturing methods, 3D printing is an additive manufacturing technology that only uses the required materials, reducing waste and material costs.

Production flexibility: 3D printing can manufacture different products on the same device as needed, without the need to replace tools or equipment. This provides greater production flexibility and the ability to quickly respond to market demand.

Small batch and customized production: 3D printing is suitable for small batch and customized production, and can produce a small amount of personalized products more economically and efficiently compared to traditional large-scale production.

High complexity and precision: 3D printing can manufacture complex geometric shapes and structures, making production more precise and refined. This is very beneficial for manufacturing high-precision parts and high-quality products.

Sustainability and environmental protection: As 3D printing is an additive manufacturing technology, it reduces material waste and energy consumption, helping to achieve sustainable and environmentally friendly manufacturing processes.

These advantages make 3D printing technology have enormous potential in many fields, driving innovation and the development of the manufacturing industry. Changing traditional manufacturing models has brought new opportunities and challenges to various industries.

How does 3D printing work?

3D printing is a manufacturing technique that converts digital models into physical objects. Firstly, computer aided design (CAD) software is used to create or obtain digital models of objects. This model can be a 3D model created by a designer or obtained by scanning real objects with a 3D scanner.

Slicing: Import the digital model into slicing software. Slicing software decomposes the model into many thin horizontal layers, each with a fixed thickness. This process is called slicing, and the data from each layer will be used to control the operation of the 3D printer.

Setting parameters: In the slicing software, set the parameters required for 3D printing, including printing speed, layer height, fill density, etc. These parameters will affect the quality and characteristics of the printed results.

Prepare the printer: Transfer the sliced file to a 3D printer. Depending on the printing technology used, corresponding materials such as plastic wire, powder, or liquid resin need to be loaded.

Printing process: Once ready, the 3D printer will stack materials layer by layer according to the specified path and hierarchy to establish objects. Depending on different printing techniques, printers may use methods such as nozzles, laser beams, electron beams, or lighting to add materials layer by layer.

Post processing: After completing printing, some post processing operations may be required. This may include removing support structures, cleaning printed objects, conducting surface treatments or further processing.

Through the above steps, 3D printing technology can convert digital models into solid objects. This additive manufacturing method provides higher design flexibility, faster prototype production, and new possibilities for small-scale and customized production.

Whatsapp

Whatsapp

Email

Email

Get a Auota

Get a Auota