Introduction to Metal Injection Molding Process Characteristics

Metal injection molding is a high-precision manufacturing process that combines traditional plastic injection molding and powder metallurgy technology. It can be used to produce metal parts with complex shapes and high density, and is usually used to manufacture small metal parts, such as mobile phone parts, medical equipment, automotive parts, etc. Common Materials for Metal Injection Molding Stainless steel Stainless steel is one of the most commonly used MIM materials, with good co

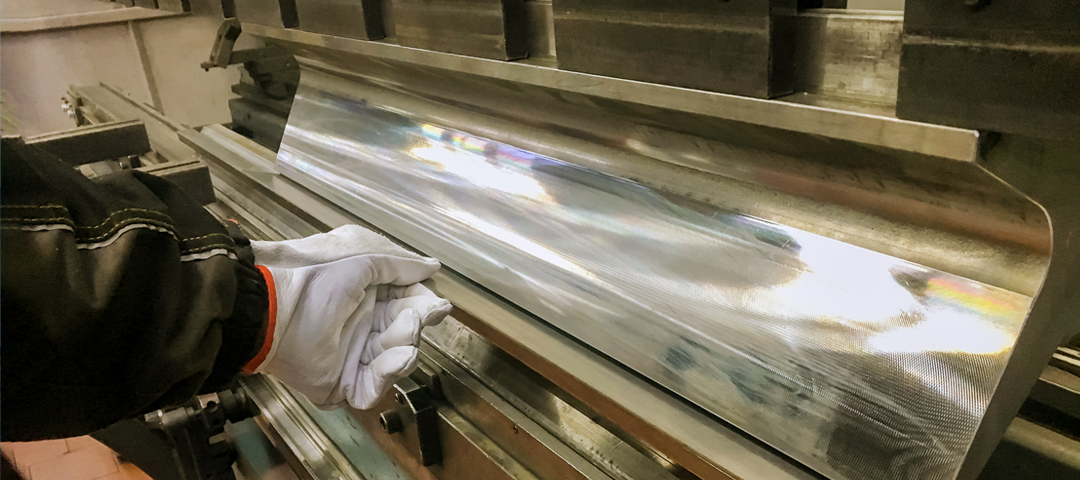

Learn MoreTechniques for Welding Stainless Steel Sheet

Welding methods for stainless steel sheets welding TIG welding is a commonly used welding method for stainless steel sheets. Use non consumable tungsten electrodes and inert gas (usually argon) to generate an arc, and manually add welding wires to form the weld seam. TIG welding can provide high welding quality and appearance, suitable for applications with high requirements for weld quality. MIG welding MIG welding is an automated welding method commonly

Learn MoreMethod of using copper in sheet metal manufacturing !

The conductivity and thermal conductivity of copper are one of its advantages in sheet metal manufacturing. Copper is an excellent conductive material, second only to silver, making it ideal for electrical applications. The use of copper plates for electrical needs in buildings can ensure good current conduction and heat dissipation, in order to maintain the normal operation and safety of equipment. In addition, the corrosion resistance of copper is also one of its advantages in shee

Learn More Whatsapp

Whatsapp

Email

Email

Get a Auota

Get a Auota